The European Spallation Source (ESS) has recently received and installed the first beam stop for the MBL section of the ESS superconducting linac. The ESS MBL beam stop was designed at the ESS in Lund (Sweden), assembled and extensively tested by ESS and Proactive R&D staff.

The beam stop is a beam-intercepting device, subject to ISO5 requirements, water cooled and movable by a pneumatic actuator in the vacuum beam pipe of the ESS proton accelerator.

The manufacturing of the beam stop involved several companies from all around Europe, including Proactive R&D in Spain and Allectra in Sheffield Park (United Kingdom). This achievement is a strong example of how science acts as a unifying force, bringing together people across borders and disciplines to tackle complex engineering challenges through shared knowledge and cooperation.

How did Allectra contribute to the project?

Allectra is a leading manufacturer and supplier of components for use in UHV environments.

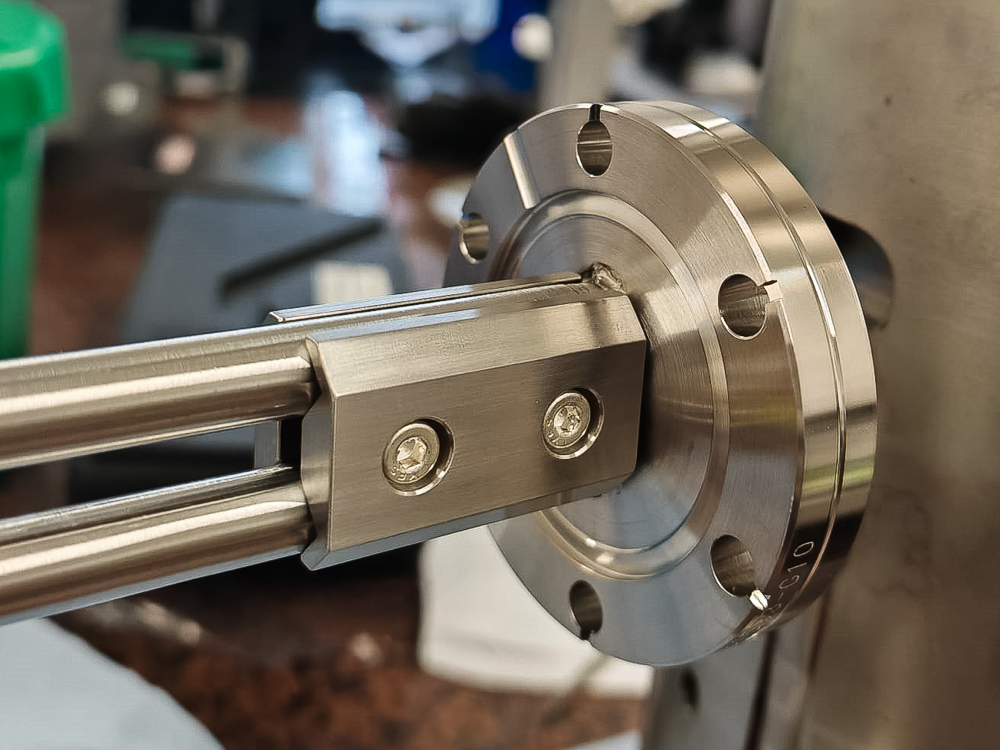

In the case of the ESS MBL beam stop, Allectra welded the vacuum flanges with a customized approach, selecting the appropriate welding method and ensuring the vacuum-tight seal.

The cooling lines were measured to be nearly 500 mm long, starting from the weld located on the flange. This measurement was critical to ensure proper fit and functionality within the assembly. During the assembly process, it was observed that a significant amount of strain would be exerted on the welds. Such strain posed a risk of compromising the structural integrity of the welds, potentially affecting the reliability of the vacuum system.

To address these concerns and mitigate the risk to weld integrity, Allectra designed and manufactured a custom strain relief specifically for the cooling pipes. This solution was implemented to reduce the likelihood of damage and ensure the long-term performance of the cooling lines.

In addition to the standardized post-weld inspections, Allectra performed all the tests that were requested by ESS. In particular, helium leak testing was thoroughly performed to demonstrate the vacuum integrity of the weld better than 10-10 mbar L/s level. At the end of the welding process, all the vacuum surfaces were free from visible defects such as pitting, cracks and indentions.

What was the main challenge?

The ESS MBL beam stop is an extremely compact device that was designed to stop the powerful beam of 250 MeV protons in the ESS superconducting linac. The beam-interceptive section of the beam stop weighs approximately 40 kg, is movable and water cooled.

In order to minimize the mechanical stress on the compact cooling pipes, Allectra customized and produced a stress-relief bracket that protects and extends the lifetime of the cooling pipes.

All the solutions were found in collaboration with the engineers at Proactive R&D (in Spain) and ESS staff in the Beam Diagnostics and Vacuum teams (in Sweden). The interdisciplinary team carefully selected materials and techniques considering the vacuum requirements, radiation resistance, weldability and outgassing.

This successful outcome reflects the power of international collaboration – bringing together manufacturers, engineers, technicians and scientists from different countries and backgrounds to complete the production and testing of the MBL beam stop that will be operated in the ESS superconducting linac.

More info can be found in the IBIC205 conference proceeding

“Challenges with the beam destinations for the ESS linac (MOPMO06)”.