Ultra-high vacuum (UHV) chambers are essential instruments for some of the world’s most challenging high-technology markets. Cryogenics, photonics, semiconductor manufacturing, and surface science research represent just a handful of the application areas that are reliant on high vacuum components to maintain a low-pressure and contaminant-free environment for optimal quality assurance and control.

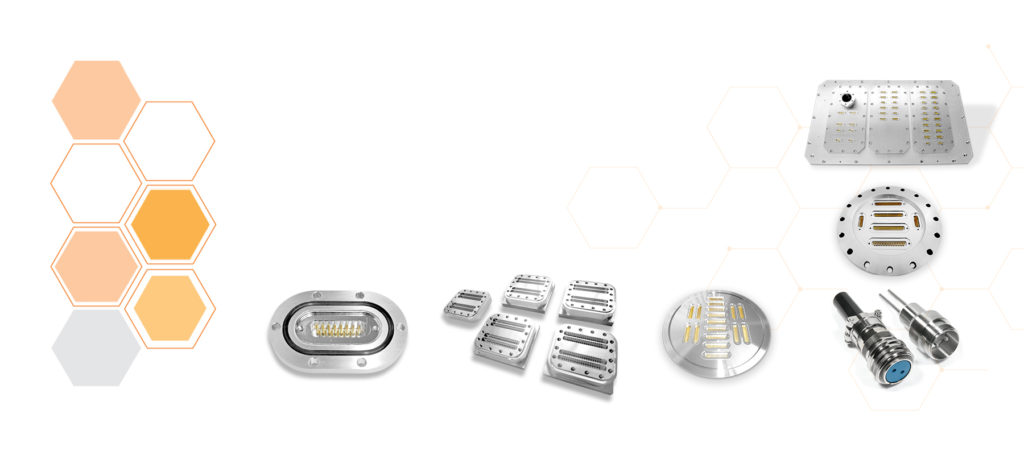

The UHV pressure regime extends below 10-9 mbar. These conditions are induced within a hermetically-sealed chamber by exhausting gases with a pumping system. Test or manufacturing procedures must then be conducted using custom high vacuum components such as interlocks, or UHV-compatible feed-throughs, to adjust the process conditions or acquire data in-situ.

Many high vacuum components are manufactured on a custom basis due to the high tolerances of specialised vacuum environments. In this blog post, Allectra outlines our method of manufacturing UHV components in more detail.

High Vacuum Components Market

Allectra was founded in Berlin in 2002, by two entrepreneurial scientists who decided on a new approach to selling high technology components for scientific markets. Our aim to develop a range of electrical feedthroughs specialised for high and ultra-high vacuum regimes has been realised in the years since, as we progressed from primarily distributing high vacuum components to manufacturing them at our own facility.

We pivoted further from distribution and assembly of vacuum systems to developing and manufacturing our own product range with our investment in a UK-facility. This enabled us to bring our high-vacuum component manufacturing capabilities in-house. Prior to this, we relied on external suppliers to machine parts, before shipping them to our European facility for welding, cleaning, and leak-checking. Now, we have total control over quality and assurance of our components with a purpose-built facility designed for both production, design and administration functions.

These capabilities are essential for manufacturing high vacuum components for challenging markets, as we can now offer guarantees to customers on critical aspects from delivery times to product consistency. We have seen a lot of companies attempting to improve their own ROIs by driving for the cheapest possible products. Our manufacturing process is based on quality and consistency, offering appreciable long-term cost savings due to product performance. This has resulted in a series of successful relationships with high profile customers around the world, including:

- CERN

- Diamond Light Source

- Rutherford Appleton Laboratory

- Synchrotron Soleil,

- ESRF

- INFN

- UK’s Science and Technology Facilities Council

We have worked closely with these clients to develop unique instruments for both industrial and academic users.

Our expertise in high vacuum component manufacturing has also resulted in the adoption of Allectra-designed products as an industry standard by European synchrotrons. We supplied water-cooled masks, scatter guards, and cooling circuits for the 102 Versatile Macromolecular X-tallogrpahy in-situ beamline at Diamond Light Source, and a series of radiation hard switches for ITER.

High Vacuum Components from Allectra

Allectra is one of the fastest-growing designers and manufacturers of UHV and high vacuum components in the world. With a commitment to unerring product quality and constant development, we provide unmatched solutions for the high technology marketplace.

If you would like to learn more, please do not hesitate to contact a member of the team directly.